- MHz Crystal- 32.768kHz Crystal

Crystal Oscillator List

- MHz Crystal- 32.768kHz Crystal

Crystal Oscillator List

- Oscillator (CMOS)- Oscillator (Differential)- VCXO- TCXO- OCXO- 32.768kHz Oscillator

Crystal Filter List

- Oscillator (CMOS)- Oscillator (Differential)- VCXO- TCXO- OCXO- 32.768kHz Oscillator

Crystal Filter List

- Monolithic Filter

Ceramic Device List

- Monolithic Filter

Ceramic Device List

- Ceramic Resonator- Ceramic Filter

SAW Device List

- Ceramic Resonator- Ceramic Filter

SAW Device List

- SAW Resonator- SAW Filter

MEMS Oscillator List

- SAW Resonator- SAW Filter

MEMS Oscillator List

- Low Power MEMS- Differential MEMS

- Low Power MEMS- Differential MEMS

All About Crystals

News > All About CrystalsAn OCXO (Oven Controlled Crystal Oscillator) is a type of crystal oscillator that maintains a constant temperature using an oven, minimizing frequency changes due to environmental temperature fluctuations, resulting in greater frequency stability.

However, the oven requires continuous operation, leading to longer startup times compared to XO and TCXO (from milliseconds to several minutes) and higher power consumption (up to a few watts, compared to milliwatts for TCXO).

1. Key OCXO Parameters

Frequency Stability: ±0.1ppm to ±1ppb

Aging Rate: ±0.2ppm/year to ±20ppb/year

Power Consumption: 1.5W to 2W (at +25°C)

2. DOCXO (Double OCXO)

For higher precision (±0.1ppb to ±0.05ppb), a DOCXO places an OCXO in a second oven, improving temperature stability to ±0.10°C, compared to ±1°C in a standard OCXO.

3. Crystal Cutting Types

The choice of crystal cutting affects temperature stability. SC cuts have a lower frequency-temperature slope than AT cuts, making them more stable under varying temperatures.

4. Advantages of OCXO

High frequency and temperature stability

Low phase noise, especially at low offset frequencies

Excellent short-term frequency stability

Low jitter (sub-hundred fs)

5. Disadvantages of OCXO

High power consumption, unsuitable for battery-powered applications

Larger size (e.g., 25×22×12.1 mm)

High cost, often significantly more expensive than TCXO

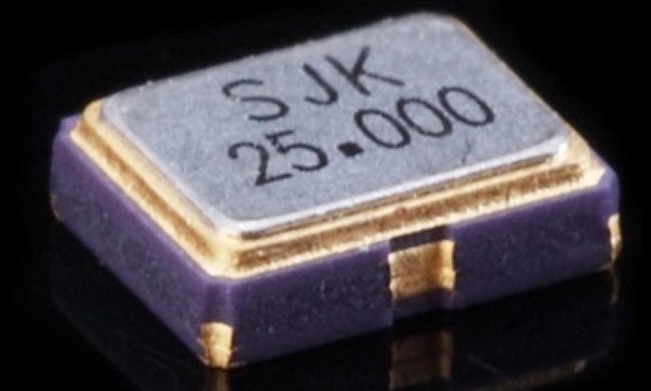

6. SJK Crystal OCXO Sizes and Part Numbers

SMD: 1X (9.7×7.5×4.1 mm), 9X (14.7×9.5×6.5 mm), 5X (25.4×22.1×11.0 mm)

THT: 1X (20.3×12.7×11.0 mm), 9X (21.0×21.0×11.0 mm), 6X (25.4×25.4×13.0 mm), 6X (36.3×27.2×13.0 mm)

7. Applications

OCXOs are widely used in communication, smart grids, industrial equipment, navigation, and military/aerospace applications, with ongoing advancements in miniaturization, precision, reliability, and power efficiency.